Mechanical

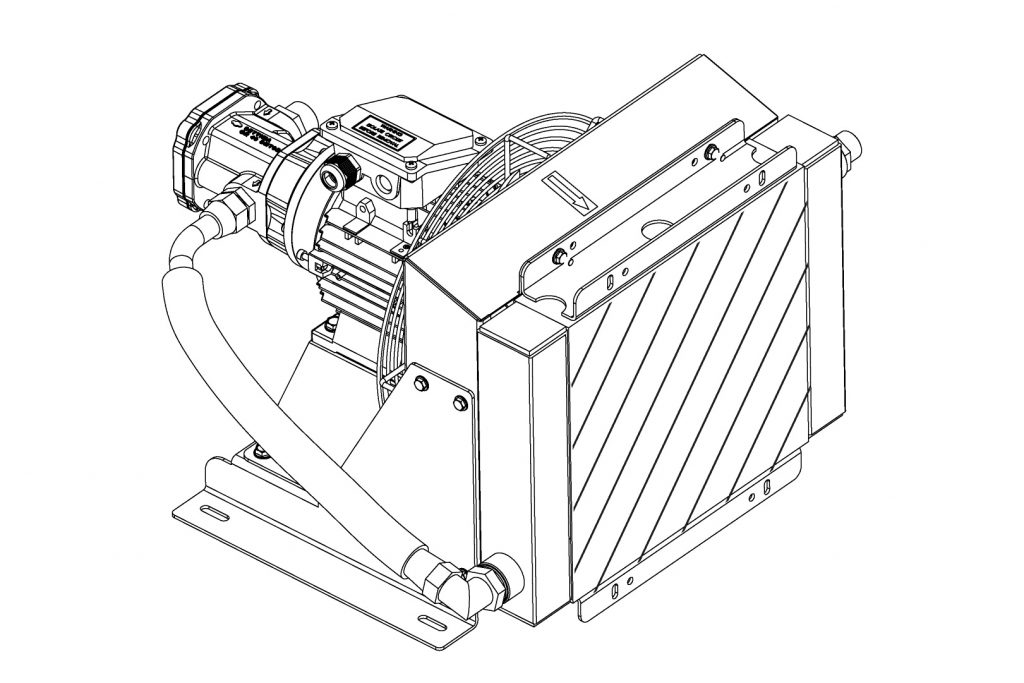

This type of power unit represent the best solution for new installations of any type, ranging from the public use lift to the goods lift and are perfectly usable for old system modernization.

These power units have a sturdy structure and a high capacity, they can contain pumps with a capacity from 55 to 380 l/min, combined with engines of 4, 5 to 37 KW, making them particularly suitable for systems with high flow rates and long strokes.

MORIS Italia uses a range of quality components that make the structure resistant - made of steel plates protected by industrial painting, tested to ensure perfect seal over time - reliable and safe in operation.

The CA model can be installed in its cabinet, while for the CA/A model a suitable machine room must be set up.

The valve block, certified up to 45 bar, made of cast iron, like the internal spools that are additionally treated with specific hardening process, ensures total efficiency and maximum safety.

The hand pump, fixed directly to the power unit tank in an easily accessible position, ensures maximum functionality in case of emergency.

Electronic

Electronic Power units are available with integrated electronic valve that involves a high comfort’s degree of speed and the best silence combined with energy efficiency. The saving on the power absorption of electricity can reach 30%.

It is ideal in civil and public environments with high traffic and strokes thanks to the modularity of the electronic valve. Thanks to the electronically-controlled valve, the same optimal performances are assured in all oil viscosity conditions, also reducing heat generation.

In all conditions of use it guarantees correct positioning at level floor.

With a compact design, electronic valves require reduced maintenance. All the operations are possible using the dedicated keypad.

The positioning in the cabinet is greatly helped by the valve and metallic tank dimensions, to ensure the system’s modularity.

Hand pump is integrated in the valve block, in a position that facilitates emergency procedures.

Specific machineroom cabinet

CA

MORIS Italia offers a series of different size cabinets in compliance with the EN 81.20: 2014, for containing the power unit and the control panel.

The recovery tank for the total oil quantity is integrated in the controller. These cabinets are an example of practicality, as the modular structure allows for the flexible positioning of the power unit and the relative tank.

.

| Mechanical | Electronical | |

| Use case | Standard lift Goods lifts | |

| Valve type | Mechanical | IValve/ LRV |

| Dimension | 1000x560x1130 | |

| Oil capacity | Utile/Working = 245 Minimo/minimum=55 | |

| Operating pressure bar | Min. = 12 Max = 45 (Mechanical Valve) | Min =12 Max =60 (Electronical Valve) |

| Pump flow | 55/250 Mechanical | 55/250 Electronical |

| Motor power | 4,5/30 (6/40) Mechanical | 4,5/30 (6/40) Electronical |

| Oil collection | Available:1014x595x573 | |

| Characteristics | High-capacity, long-travel elevators | |

Oil collection tank in compliance with the EN 81.20: 50.

Recommended for public buildings, hospitals, high-traffic facilities, the use guarantees optimum operation of your lift in high traffic conditions. Available for all models of hydraulic power units.

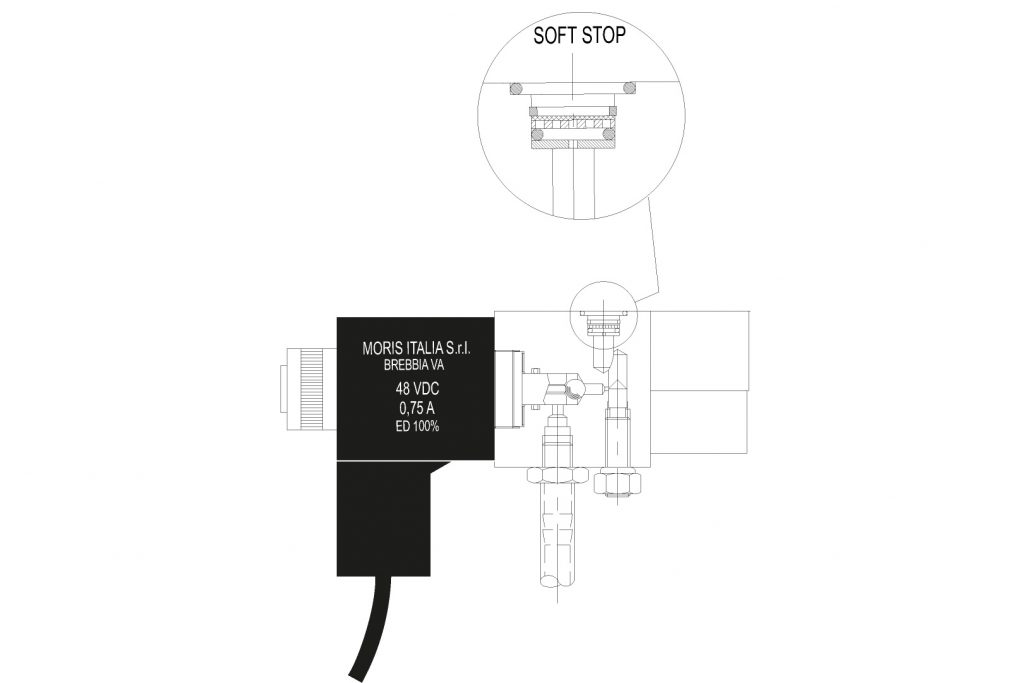

Suitable for maximum comfort in the installations at hotels, luxury facilities, health clinics, the SOFT-STOP valve intervenes to adjust the phase of arrest in a gentle way cabin in all load conditions.

Recommended for lifts, car lifts systems, high low, ensures the maintenance of the car at the door level by increasing the safe loading and unloading operations. The power (2.2 kW) of the auxiliary motor reduces power consumption and engine wear group / main pump.

Recommended for lifts, car lifts systems, high low, ensures the maintenance of the car at the door level by increasing the safe loading and unloading operations. The power (2.2 kW) of the auxiliary motor reduces power consumption and engine wear group / main pump.