Kit for the Unintended Movements of Hydraulic lifts “KMI”

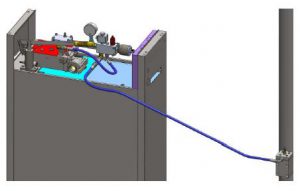

MORIS Italia developed an effective and original system to prevent unintended movements of hydraulic lifts. The system uses the natural hydraulic redundancy of the rupture valve, present on the vast majority of the hydraulic lifts: an hydraulic actuator pilots the closure of the rupture valve if the electronic card (which is part of the KMI kit) detects an unintended movement, thus causing the immediate stop of the car, independently from the actual load inside the car. The KMI kit does not introduce additional pressure losses in the main hydraulic piping, does not complicate the emergency lowering (no contemporary activation of two valves), does not affect the dimensions of the main distributor valve and it is not necessary to implement monitoring functions inside the control panel. The hydraulic actuator is now pre-assembled on the power unit, in order to simplify the elevator commissioning, and it has few hydraulic accessories that help the maintenance operations. The actuator recharging procedures have been simplified and technical solutions have been implemented in order not to recharge the actuator frequently. In ordering phase it is only needed to communicate the distance between the actuator and the rupture valve, for the hydraulic connection between the two components, by mean of a flexible hose.